50 Wrought iron gates - attractive classic gate designs - Art Metal Manufacturer in Viet Nam

1. Wrought iron

On festivals honoring the gods, people first learned about and used iron in the 12th century BC. Besides that, iron was gradually employed as a tool for labor to sustain human life. Then, the most advanced battle weapon of the time was made of iron.

But it was not until the 16th, 17th, and 19th centuries that the art of iron forging flourished in construction and architectural decoration. In that time, the most popular works in history have been done. To be more specific, outstanding works such as the Louvre Museum (Pari), Eiffel Tower, Notre-Dame de Paris, churches in Spain, ... with many designs of railings, stairs, gates, fences, which are sophisticated and magnificent. These places are considered the origin of the art of iron forging. Furthermore, the wrought iron gates and fences over the years have maintained their artistic and utilitarian values while using archaic forging techniques and the deft hands of workers in the past.

At that time, the craftsman would sketch designs on paper in pencil before creating artistic wrought iron gates and fences for villas and castles. They then used their imagination and experience to bend, shape, and assemble each pattern into full sets of villa gates. Clearly, manual bending requires a lot of time and effort.

.jpg)

2. Wrought iron gate

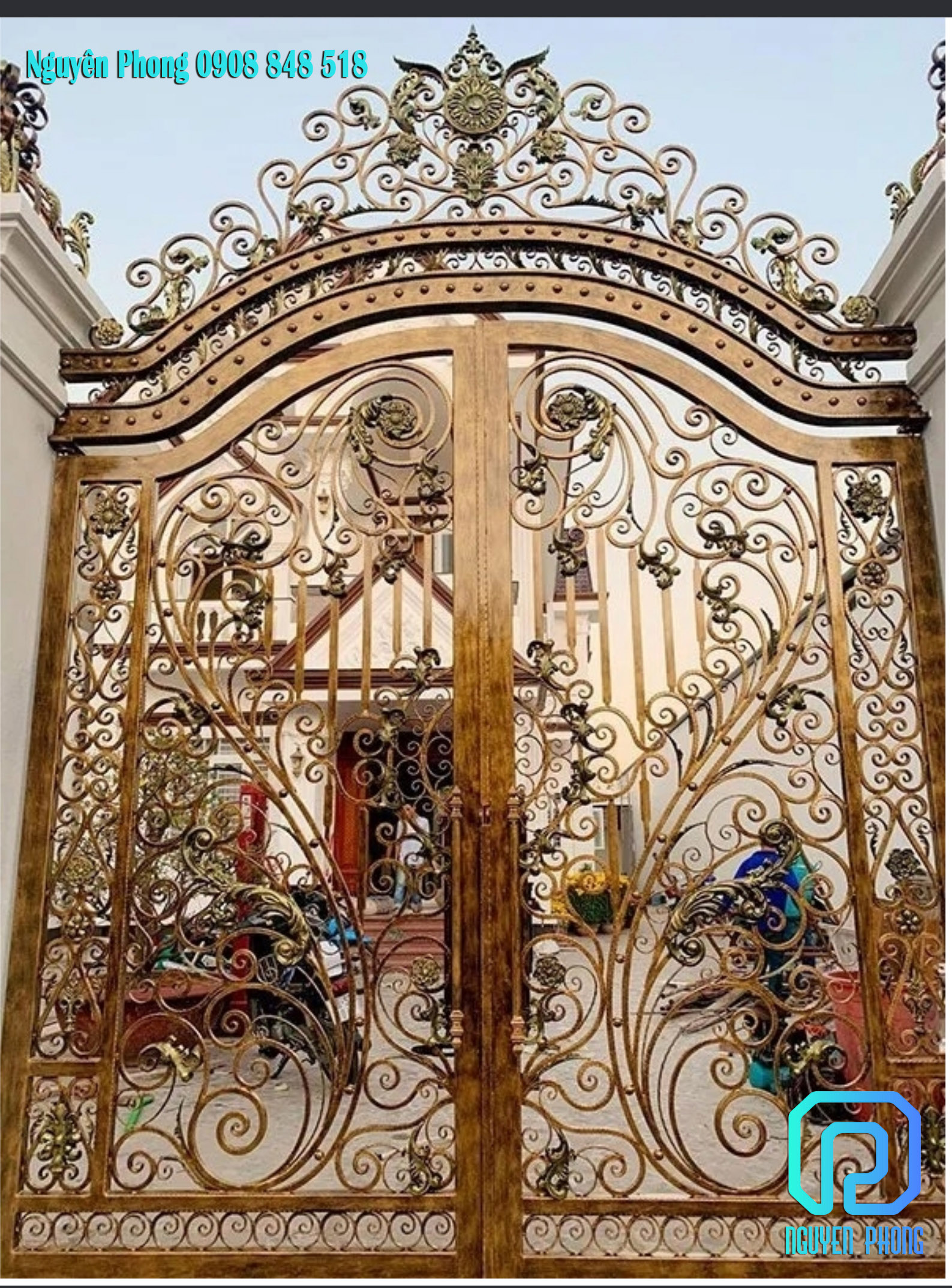

Today, with the support of machines, the iron gate design drawings are gradually becoming more elaborate and complex. Therefore, the wrought iron gates are made with a pattern that is almost exactly proportional to the 2D drawing. It is worth noting that although this speeds up the work process, the manual production stage remains at the core of each iron gate.

Each iron art production facility must really be a place to love and honor those values to be able to make quality wrought iron gates that exceed customers' expectations.

When the magnificent spirits of the French were "brought" to Vietnam, they crept into Vietnamese motifs and architecture. The distinct art of wrought iron gates and traditional castle architecture were made for each other.

When building a house, homeowners always carefully choose wrought iron gates with a design that matches the style of the house and their personal preferences. In particular, customers buying wrought iron gates around the world will have stricter requirements and desires to suit the culture and nature of the project. To be more specific, we continuously improve and upgrade the criteria of 2D and 3D design, paint color, product smoothness, factory image, professional workflow, and competitive price.

The wrought iron gate will be balanced before it is built with a number of variables, including technique, durability, materials, painted surface, and particular requirements for personal aesthetics, in addition to the demand for a monumental design, raising the level of the villa. The reason is that the artistic iron gate design in the overall architecture of the villa also shows a part of the individual personality and style of the owner of that villa.

Nguyen Phong Metal's wrought iron gate products are loved by many customers around the world. Typically, we have exported them to countries such as Canada, the USA, Australia, Spain, and Cambodia,...

Specifically, our customers are owners of individual villas, design companies, construction companies, and housing project investors all over the world.

3. Structure and design of wrought iron gates

The library of wrought iron gates is large and diverse. Moreover, each iron gate design is unique to suit individual needs and desires.

The top, middle, and bottom of the gate are the three main parts of a wrought iron gate. Gate height is calculated from the ground surface to the highest point of the gate.

- The top of a wrought iron gate: The design is sophisticated and elegantly rises in the middle like a crown. The top can be designed to be connected with the body for gates below 3500mm high, or designed to be fixed to the post for gates over 3500mm high.

- The middle of a wrought iron gate: using 40x80mm, 50x100mm, or 60x120mm iron tubes for the gate frame with a thickness of 2-3mm. The gate body is usually designed with accents and accessories that are not too tight but still ensure safety protection factors.

- The bottom of the gate: Unlike the Western style, the design of the bottom of the gate in Vietnam often has a simple but thicker pattern (fewer gaps) to prevent mice and protect pets in the house.

- Materials for decorative patterns are plentiful and more diverse; flat bar, square solid iron, and round bar iron, for example.

In addition, wrought iron gates are often large and heavy, so they are often operated by integrated automatic control motors (especially garage gates). There are two types of motors commonly used: underground gate motor and swing gate motor. Moreover, Nguyen Phong Metal believes in using motors imported from European brand names.

Customers in both local and exported markets who come to Nguyen Phong Metal have very high standards for the quality of the products and have their own style of selecting samples. Some people want robust, solid designs; some prefer delicate, gently bending details; some prefer to be understated and minimalist; and still, others want their wrought iron gate to be distinctive. The Nguyen Phong Metal Library has more than 500 models of the most beautiful wrought iron gates with many different design styles. Specifically, there are samples collected and learned from many countries around the world, and many other samples are designed specifically at the request of Nguyen Phong Metal's customers around the world.

For each project, we always design and adjust 2D and 3D drawings until we get approval and satisfaction from our customers. Especially for customers importing Nguyen Phong Metal's wrought iron gate products, we understand that customers will feel secure when working with a reputable and professional art metal manufacturer. Besides, we have a lot of experience in exporting art iron items to many different countries around the world, so we believe that we can meet the needs of customers in the best way.

4. Production materials and paint colors

In Western countries, most wrought iron gates are minimalistic in design with few floral accessories. The iron color is simply black or classic brown. Except for some special iron gates, they are processed more elaborate than usual, like a handicraft painting.

We understand the demand for iron gates and fence products from customers all over the world. In Vietnam, we have the advantage of human resources, so we can therefore bring you the best iron art products at the most competitive prices.

The material warehouse is always full of iron samples, such as:

- Iron sheet: 1.6 - 20mm thickness, 1200x2400mm and 1500x6000mm size.

- Flat bar, round bar, square solid iron, square iron tube, rectangular iron tube, and twisted square bar, etc with all sizes and specifications.

- Other materials according to production requirements,

- Materials have a clear and complete origin.

Material details are clearly described in the Quotation with specific images.

2-part Epoxy paint is used for all our products, and we always encourage our customers to choose paint from Jotun and Asia brands. These are the best paints for fine art iron products. The average lifespan is up to 5 years (for products not applying the hot-dip galvanization method) and more than 15 years (for products applying the hot-dip galvanization method).

5. Production at the Nguyen Phong Metal Art Metal factory:

Following the customer's approval of the design drawing, Nguyen Phong Metal proceeds with making frames, bending and forging iron patterns, and connecting them together using 1:1 scale drawings to guarantee utmost precision.

Wrought iron gates are works of iron art with a strong focus on aesthetics. Workers with extensive production expertise and competence are required to complete the entire production process. Additionally, Nguyen Phong Metal's Quality Control (QC) personnel are always the strictest quality controllers, ensuring that the products are of the highest caliber for clients.

The painting stage is equally important after forging, bending, and assembling the gate pattern.

Before painting, items are hot dip galvanized to prevent rust (according to the customer's request). Nguyen Phong Metal encourages people to choose this option. Despite the higher cost than usual for galvanization and workers who are responsible for treating surfaces, they also prefer galvanization because it helps protect products from rusting and prolong the life of the wrought iron gates.

The painting stages will go through steps such as cooling - treating the surface to make sure it is smooth, 2-layer primer painting, 2-layer color-painting, and gloss-painting 1-2 times.

Products are thoroughly tested before being shipped and delivered to customers.

6. Construction and installation of wrought iron gates at the construction site.

- Nguyen Phong Metal Fine Art Iron Company specializes in measuring, designing, manufacturing, and constructing a full package of front doors, fences, and railings, as well as wrought iron stairs for high-class classic villas.

To make the installation process go quickly and smoothly, technical staff must carefully measure and agree on the construction plan with the parties at the construction site.

Due to the size and weight of the majority of the wrought iron gates, cranes are frequently used during construction.

Handle defect of gate surface aesthetics before handing over and putting into use.

Construction is a crucial stage that demonstrates each supplier's operational capability, attitude, and professional work ethic. For these reasons, Nguyen Phong Metal always receives respect from customers for the products that we make with enthusiasm and passion.

7. Exclusively designed iron gate designs in Nguyen Phong Metal.

- The wrought iron gate models inherit the classic designs.

- The wrought iron gates model is designed specifically to suit the style and preferences of Vietnamese people.

- The iron gate designs in Nguyen Phong Metal are loved by international customers.

With more than 10 years of experience in both local and export markets, we are able to offer advice for proper designs, most economical production solution and safe transportation. Working with Nguyen Phong Metal, you can rest assured that your project will get the best value in terms of quality, art and money you paid.

NGUYEN PHONG METAL JSC

OFFICE ADDRESS: 323A Le Quang Dinh, Ward 5, Binh Thanh District, HCMC

FACTORY 1: Vinh Loc Industrial Zone, Binh Chanh Dist, Ho Chi Minh City, Vietnam

FACTORY 2: Binh Giao, Thuan An Dist, Binh Duong Provice, Vietnam

Hotline: +84 908 848 518 (zalo, viber, whatsapp)

Email: Sales@nguyenphongcnc.com - phuongdangthy@gmail.com

Website: http://nguyenphongcnc.com/

Fanpage: https://www.facebook.com/nguyenphongmetal/

Alibaba site: https://npwroughtiron.trustpass.alibaba.com